SIEB & MEYER Introduces Innovative SpindleServiceTool (SST)

Press releases

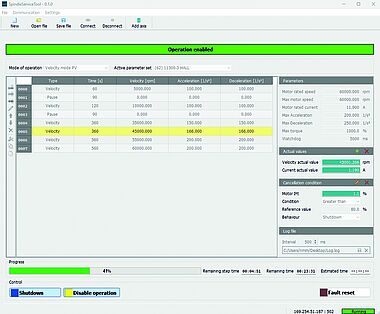

Efficient Automation of Acceptance and Running-in Tests

The new SpindleServiceTool (SST) by SIEB & MEYER helps spindle manufacturers and repair shops to optimize their quality management and save time and costs. This makes testing and running-in of spindles much simpler. The efficient and flexible automation solution now supplements the parameterization software drivemaster4 of the German high-speed specialist based in Lueneburg.

Frequency converters of the product family SD4x by SIEB & MEYER are used successfully in numerous serial products such as lathes and grinding machines. In addition, the manufacturers of the processing spindles often use SD4x devices internally. After manufacturing or repair, the spindles usually must pass a final acceptance test. They are exposed to different speed cycles over several hours to ensure smooth operation under real conditions. Especially for spindles with bearings, this test has a double function: in addition to providing proof of quality, it also ensures a defined running-in process for the new ball bearings.

Flexible and scalable test runs

In order to automate these test processes, the spindle manufacturers previously had to develop complex test setups with external controls or PLCs – a time-consuming and cost-intensive project. With the SST tool, SIEB & MEYER offers an uncomplicated solution for frequency converters of the SD4x family that saves time as well as resources. The PC software allows parallel control of up to four frequency converters, creation of individual speed cycles and running these automatically. This increases the flexibility and scalability of the test operation and eliminates the need for external control elements.

The new SpindleServiceTool is available to customers free of charge in addition to the parameterization software drivemaster4. "With SST, we offer spindle manufacturers and repair shops an innovative automation solution that significantly simplifies the testing and running-in of processing spindles while increasing flexibility and efficiency," explained SIEB & MEYER CTO Torsten Blankenburg. "Thanks to parallel operation of several frequency converters, users can easily increase the test capacities."