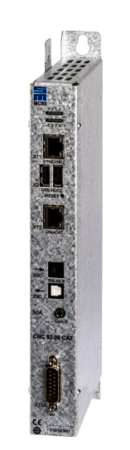

CNC 93.00 CAT

The cost-optimized CNC control for routing applications

CNC 93.00 CAT by SIEB & MEYER offers individual and cost-optimized solutions for routing machines in the PCB industry and meets all the requirements of a modern CNC. It is characterized by the powerful software and processor technology proven in CNC 93.00 and is equipped with an EtherCAT interface for servo drives and frequency converters. SIEB & MEYER frequency converters of series SD2S and SD4S for asynchronous and synchronous spindle motors can also be connected via this interface.

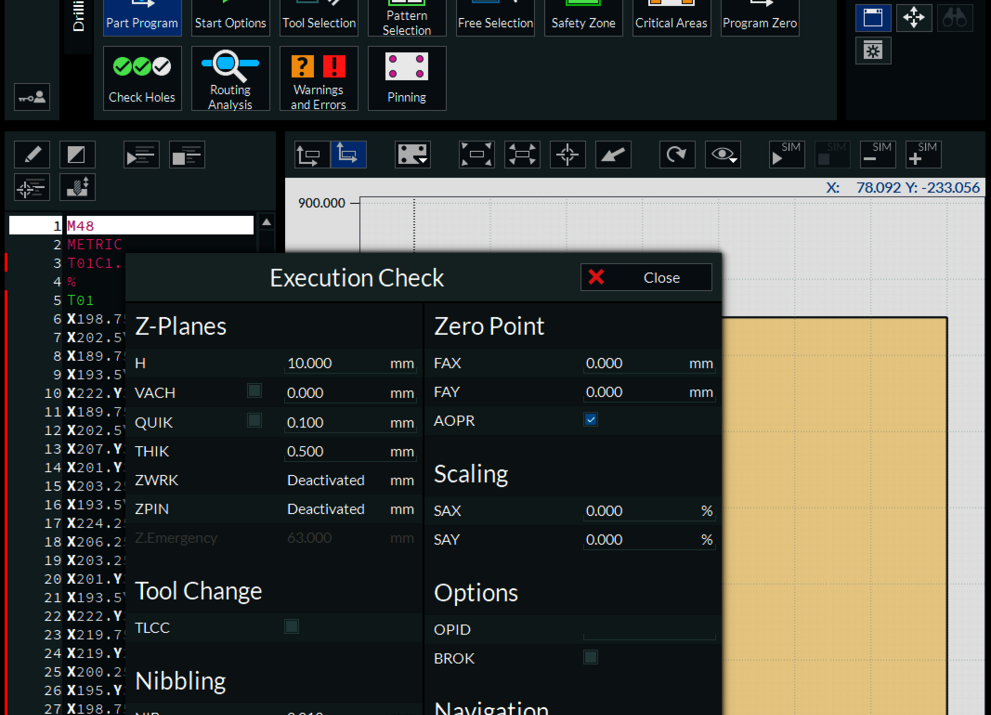

Easy and error-free operation

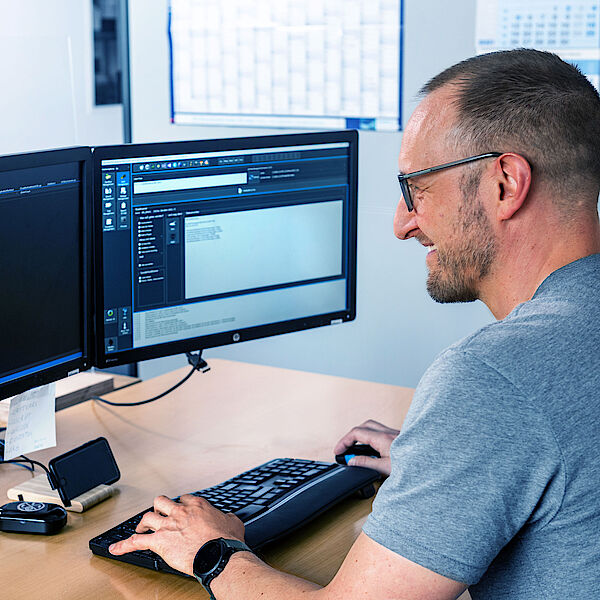

Following the design of the very successful CNC 93.00, the user interface of CNC 93.00 CAT allows intuitive operation requiring only a short training period. In addition, the high clearness and easy-to-use navigation significantly reduce incorrect user input.

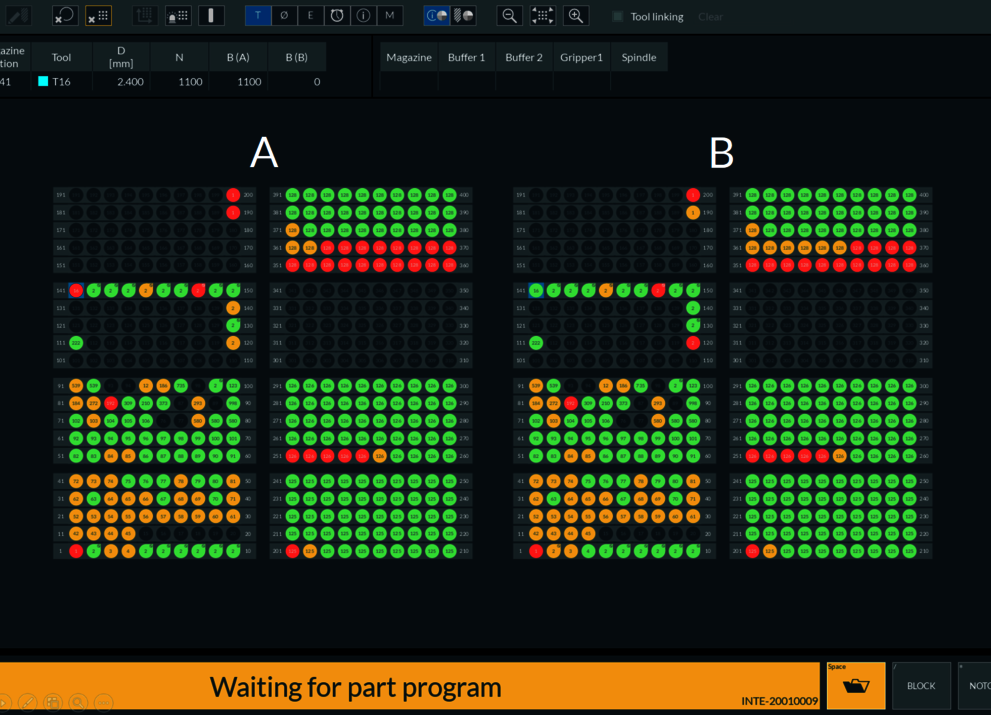

Extensive software functions

In addition to intelligent tools for quality analysis and extended routing radius compensation, the CNC 93.00 CAT software also offers extensive setup options by using scripts that can be adapted by the machine manufacturer as required. The number of CNC commands within a routing program can be significantly reduced and faulty routing paths can be avoided. In addition, the CNC 93.00 CAT has an extended PIN manager and enables the entire routing contour to be analyzed before machining begins.

The Interfaces of CNC 93.00 CAT

- X11 Ethernet port for connection to a PC

- X12 EtherCAT connection for servo drives and frequency converters

- X90 SMLink 9 data input via fiber optic connection from I/O modules

- X90 SMLink 9 data output via fiber optic connection to I/O modules

- X10A I/O 24VDC logic power supply and machine stop

Enrergy Efficieny and Performance

The modern and modular hardware architecture of CNC 93.00 allows extremly dynamic and precise machine drives with highest quality and little need for space. To reduce the required energy all servo drives and frequency converters are supplied via a DC bus of the central power supply. This minimizes costs and the required space.

CNC 93.00 CAT – Fit for the Future

CNC 93.00 CAT by the world market leader SIEB & MEYER in the field of CNCs for PCB routing machines is the perfect answer to all demands of high-precision, routing machines to be met by modern CNC controls.

Industry 4.0

With the help of SM IIoT Connect the CNC 93.00 CAT can be extended by further communication interfaces, for example, the widely used OPC UA. This makes it easy to integrate the controller into industrial 4.0 concepts and to meet the extended requirements of routing machines in a future-proof and convenient way.

News

Control Clear Functions Easily with User Level

More Efficient Operation Thanks to Customized User Interface

Save Costs with Customized Tool Life

Feel free to contact us

CNC 93.00 CAT

The cost-optimized CNC control for routing applications

CNC 93.00 CAT by SIEB & MEYER offers individual and cost-optimized solutions for routing machines in the PCB industry and meets all the requirements of a modern CNC. It is characterized by the powerful software and processor technology proven in CNC 93.00 and is equipped with an EtherCAT interface for servo drives and frequency converters. SIEB & MEYER frequency converters of series SD2S and SD4S for asynchronous and synchronous spindle motors can also be connected via this interface.

Easy and error-free operation

Following the design of the very successful CNC 82.00, the user interface of CNC 93.00 CAT allows intuitive operation requiring only a short training period. In addition, the high clearness and easy-to-use navigation significantly reduce incorrect user input.

Extensive software functions

In addition to intelligent tools for quality analysis and extended routing radius compensation, the CNC 93.00 CAT software also offers extensive setup options by using scripts that can be adapted by the machine manufacturer as required. The number of CNC commands within a routing program can be significantly reduced and faulty routing paths can be avoided. In addition, the CNC 93.00 CAT has an extended PIN manager and enables the entire routing contour to be analyzed before machining begins.

The Interfaces of CNC 93.00 CAT

- X11 Ethernet port for connection to a PC

- X12 EtherCAT connection for servo drives and frequency converters

- X90 àSMLink 9 data input via fiber optic connection from I/O modules

- X90 ß SMLink 9 data output via fiber optic connection to I/O modules

- X10A I/O 24VDC logic power supply and machine stop

Enrergy Efficieny and Performance

The modern and modular hardware architecture of CNC 93.00 CAT allows extremly dynamic and precise machine drives with highest quality and little need for space. To reduce the required energy all servo drives and frequency converters are supplied via a DC bus of the central power supply. This minimizes costs and the required space.

CNC 93.00 CAT – Fit for the Future

CNC 93.00 CAT by the world market leader SIEB & MEYER in the field of CNCs for PCB routing machines is the perfect answer to all demands of high-precision, routing machines to be met by modern CNC controls.

![[Translate to Englisch:] CNC 95.00](/fileadmin/_processed_/2/f/csm_Produkt_Teaser-1000x1000_Plattform_64b019ae92.png)

Industry 4.0

With the help of the SM IIoT Platform the CNC 93.00 CAT can be extended by further communication interfaces. These include, for example, the widely used OPC UA. This makes it easy to integrate the controller into industrial 4.0 concepts and to meet the extended requirements of drilling machines in a future-proof and convenient way.

Applications

About SIEB & MEYER

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 260 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners