The optimal products for your PCB drilling machine

PCB drilling of printed circuit boards is determined by continuously increasing technical requirements of the electronics industry, as well as the requirements for cost optimization. The steadily rising level of integration of the electronic components requires to improve drilling accuracy and process reliability.

At the same time, the prevailing pricing pressure on electronic devices demands a continuous step-up in productivity. The CNC controls by SIEB & MEYER contribute to meet these challenges with your machine not only today, but also in the future.

Product Overview

A. CNC Control Systems

| Device series | Description | Drive package | |||||

|---|---|---|---|---|---|---|---|

| CNC 95.00 | THE NEW GENERATION: Complete hardware and software solution for the operation of a PCB drilling machine | Servo amplifier and frequency converter for the operation of all motion axes/drilling spindles included | |||||

| |||||||

| Device series | Power range | Input voltage | Technology | Speed (frequency) | Version | Communication | Safety functions |

| SD2S-FPAM | 1.5 .. 3.8 kVA | 115 .. 230 VAC | Controlled DC link (PAM, FPAM) | 480,000 rpm (8,000 Hz) | Single-axis device for the operation of synchronous and asynchronous spindles | RS232, CAN Bus, EtherCAT | STO |

| FC2 | 13 kVA | 230 .. 480 VAC | Regulated DC link (PAM) | 500.000 rpm (8.333 Hz) | Multispindel device | RS232/485, CAN Bus, EtherCAT | STO |

More Efficient Operation Thanks to Customized User Interface

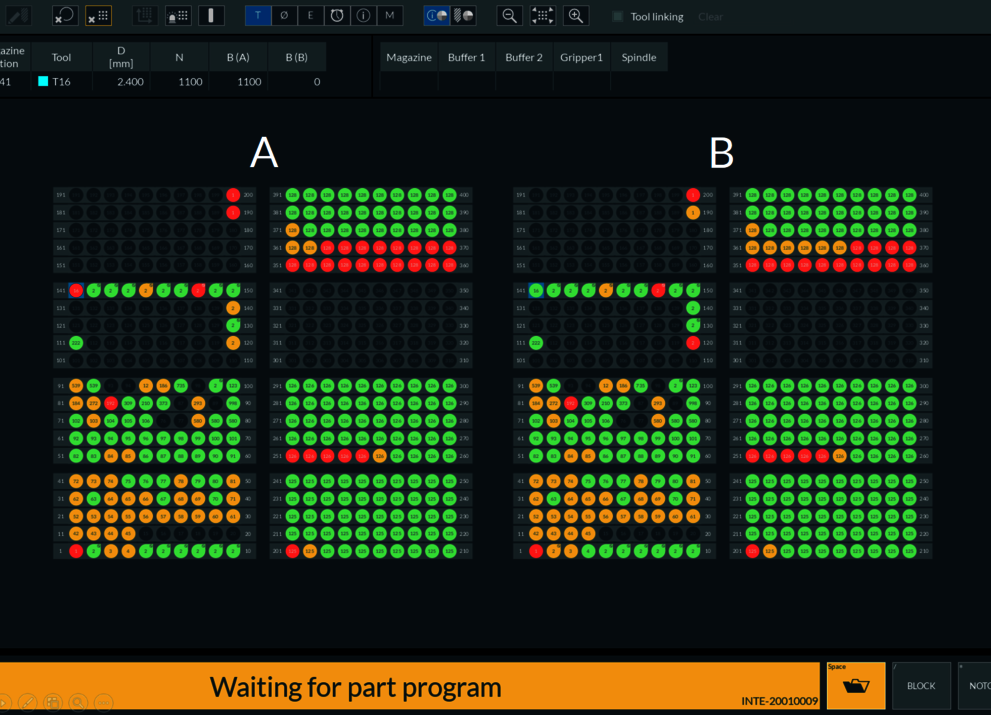

Save Costs with Customized Tool Life

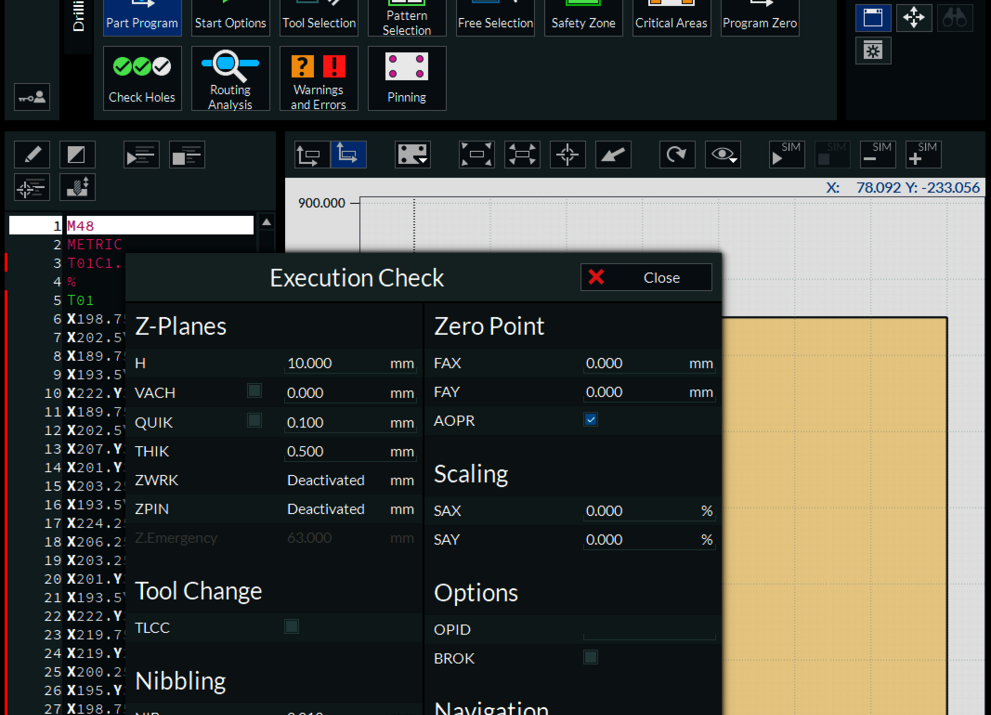

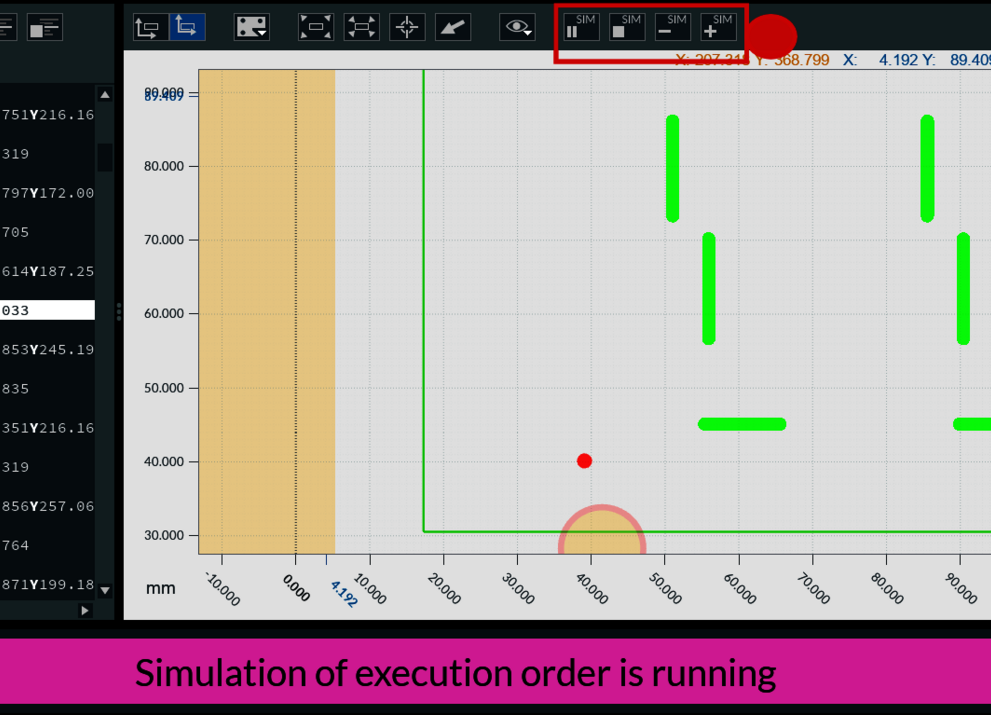

Program simulation promotes error-free production

Control systems & drive technology – customized for your application

With our experience from customized drive systems that are meanwhile produced in large series and as well as our standard devices, we are supporting you from the project planning phase to the series production.