CNC 93.00

CNC 93.00 sets standards

CNC 93.00 sets new standards in control technique for PCB routing machines. Equipped with the latest processor technologies and programming tools as well as future-proof interfaces for data retrieval this CNC leaves nothing to desire.

CNC 93.00 benefits from more than 40 years of experience in CNC technology making PCB routing applications even more user-friendly, efficient and flexible.

Adaptions Made Easy

The scripting feature of CNC 93.00 offers machine manufacturers a new dimension of quick and protected adaptation of machine functions and sequences. The programming is clear and well-structured enabling even technicians with less experience in this field to use this feature.

Avoid Production Waste and Idle Times

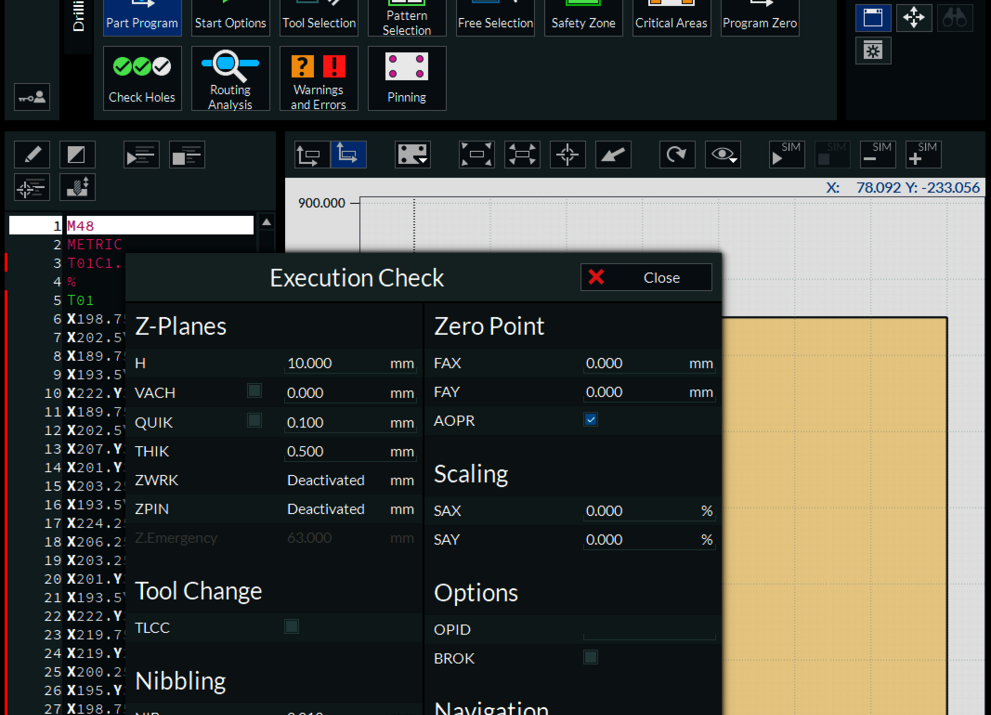

The analysis and simulation of the complete part program before the first run allows reliable error detection prior to production start and prevents production waste. Besides, the exact calculation of the time required for the execution of the part program in CNC 93.00 supports optimal planning of production processes for PCB routing machines.

Easy and Error-Free Operation

Following the design of the very successful CNC 82.00, the user interface of CNC 93.00 allows intuitive operation requiring only a short training period. In addition, the high clearness and easy-to-use navigation significantly reduce incorrect user input.

Industry 4.0

With the help of the SM IIoT Platform the CNC 93.00 can be extended by further communication interfaces. These include, for example, the widely used OPC UA as well as various API interfaces. This makes it easy to integrate the controller into industrial 4.0 concepts and to meet the extended requirements of drilling machines in a future-proof and convenient way.

Enrergy Efficieny and Performance

The modern and modular hardware architecture of CNC 93.00 allows extremly dynamic and precise machine drives with highest quality and little need for space. To reduce the required energy all servo drives and frequency converters are supplied via a DC bus of the central power supply. This minimizes costs and the required space.

CNC 93.00 – Fit for the Future

CNC 93.00 by the world market leader SIEB & MEYER in the field of CNCs for PCB routing machines is the perfect answer to all demands of high-precision, routing machines to be met by modern CNC controls.

SM IIoT Connect

In the CNC 95.00/CNC 93.00, the OPC UA interface is always available as a modern and flexible solution.

SM IIOT Connect clearly displays all important production parameters and also enables the CNC 95.00/CNC 93.00 to be automated via the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

Technical Details CNC 93.00

Motion Controller MC93

- CPU: Intel® Quad-Core™

- SDRAM: 4 GB DDR3

- Flash: 4 GB

- 2 x USB host

- 1 x COM interface

- Interface to PC: Ethernet

- 2 x digital bus via optical fiber connector (120 Mbit/s) to the drives MD95, FC95

- 1 x digital bus via optical fiber connector (12 Mbit/s) to the I/O system 84.06

- SD card (option)

- SSD hard disk (option)

Servo drive MD95 Nano with central voltage supply PS95

- Mains voltage 3 x 230 VAC to 250 VAC

- Rated current IN: 2 Arms to 32 Arms

- Peak current IS: 14 Arms to 57 Arms

- 1-axis, 2-axis, 4-axis and 6-axis design for rotary and linear AC motors

- Evaluation of incremental encoder, absolute encoder or linear measuring system TTL

- Digital bus via optical fiber cable (120 Mbit/s) for connection to MC93

Frequency converter FC95 with central voltage supply by PS95

Asynchronous spindles:

- Rated power: 6 kVA to 15 kVA

- Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

- Rated current IN: 21 Arms to 35 Arms

- Peak current IS: 42 Arms to 71 Arms

- Output frequency f: 5,834 Hz

- Evaluation of speed sensors or operation without sensors

- Digital bus via optical fiber cable (120 Mbit/s) for connection to MC93

Decentral I/O-System 84.06

- DC supply: +24 V

- Inputs and outputs: 768

- Inputs: +24 V (active-high)

- Outputs: +24 V, 350 mA / short-circuit proof

- Data transmission via optical fiber cable (12 Mbit/s) / CRC monitored

- Serial interface for external PLC

- PD-Box with integrated interface for tool measurement and tool test

Comparison CNC 8x.00 - CNC 9x.00 by SIEB & MEYER -

Control Features

| CNC 8x.00 (Launched in 2005) | CNC 9x.00 (Launched in 2018) | Remark | |

|---|---|---|---|

| CPU processor | Coldfire MCF | Intel Atom | The choice of chips for the CNC 8x.00 is based on a 20-year-old architecture. Therefore, functionality of the CNC 8x.00 can only be retained and not adapted. The processor is not avaliable anymore on the market. SIEB & MEYER has a large stock, but this is ultimately limited. A certain amount of safety stock must be kept for service purposes. |

| Clock frequency | 220 MHz | 4x1.9 GHz | CNC 9x.00: excellent |

| Master storage | 16 MB RAM, 2 MB DPRAM | 4 GB DDR3 SDRAM, 4 GB eMMC FLASH | CNC 9x.00: excellent |

| Usability | Graphic program visualization. Intuitive and user-friendly human-machine interface, easy to operate and easy to learn. | Improved faster graphic program visualization. Intuitive and user-friendly human-machine interface, easy to operate and easy to learn. The simple customization of the interface according to process requirements can be realized by the OEM. | The operation mode and the use of command are completely consistent in both CNCs. The user interface of the CNC 9x.00 is more user-friendly. The simple customization for the end customer is particularly advantageous. |

| Compatibility and expandability | Master software planning and machine sequences. Non-standard modular upper programming limit. | Functional modularity via scripting. Support for technology upgrades in the future. | CNC 9x.00: excellent |

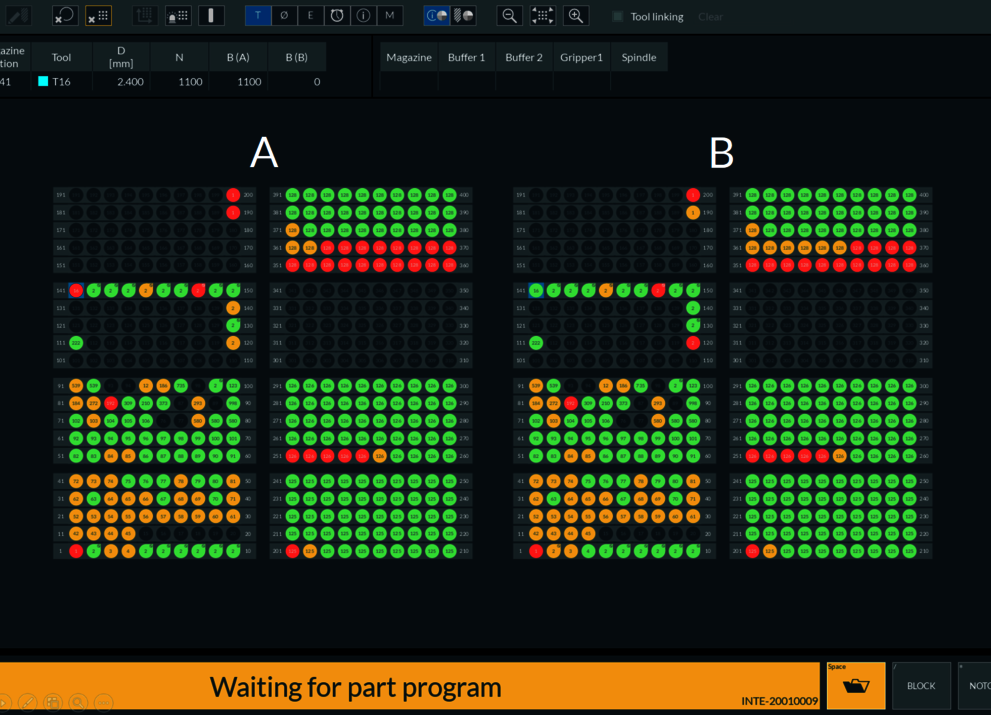

| Puzzle mode | Single-axis panels | Multi-axis panels | CNC 9x.00: excellent |

| Communication interface | Based on the SMDDE protocol (SIEB & MEYER own protocol) | SM IIoT Connect is included in the scope of delivery by default. OPC UA servers are available and support Industry 4.0 standards. | CNC 9x.00: excellent |

| Applicable scenarios | Traditional execution, small and middle serial production, stable environment | Production in large quantities, tailor-made for the modern factory | CNC 9x.00: excellent |

| Productivity | Standard 6 spindles and max. 6-axes IWS techniques | DWS 8/10/12 spindles, reserve for more axes | CNC 9x.00: excellent |

| Automization | Sequences, SMDDE | Fast process adaptaption by PEM scripts and standard OPC UA connection | CNC 9x.00: excellent |

| Quality assurance | Evaluating the logs retrospectively | Extensive logging through evaluation in real-time PDL data | CNC 9x.00: excellent |

| Data evaluation | Limited storage availability | Considerably more camera data and SLM surface memory possible | CNC 9x.00: excellent |

| Production Issues | Corrective drilling program, limited function | Easy process continuation of processes for the operator by the PIT function (production issue table) on the basis of permanent process data collection | CNC 9x.00: excellent |

| User interface funtions | Clear and fix user interface | The user interface can be adapted to the requirements of the customer | CNC 9x.00: excellent |

News

Control Clear Functions Easily with User Level

More Efficient Operation Thanks to Customized User Interface

Save Costs with Customized Tool Life

Feel free to contact us

![[Translate to Englisch:] CNC 93.00](/fileadmin/_processed_/9/b/csm_Header_CNC93_829dcc0692.png)

CNC 93.00

CNC 93.00 sets standards

CNC 93.00 sets new standards in control technique for PCB routing machines. Equipped with the latest processor technologies and programming tools as well as future-proof interfaces for data retrieval this CNC leaves nothing to desire.

CNC 93.00 benefits from more than 40 years of experience in CNC technology making PCB drilling applications even more user-friendly, efficient and flexible.

Adaptions Made Easy

The scripting feature of CNC 93.00 offers machine manufacturers a new dimension of quick and protected adaptation of machine functions and sequences. The programming is clear and well-structured enabling even technicians with less experience in this field to use this feature.

Avoid Production Waste and Idle Times

The analysis and simulation of the complete part program before the first run allows reliable error detection prior to production start and prevents production waste. Besides, the exact calculation of the time required for the execution of the part program in CNC 93.00 supports optimal planning of production processes for PCB routing machines.

Easy and Error-Free Operation

Following the design of the very successful CNC 82.00, the user interface of CNC 93.00 allows intuitive operation requiring only a short training period. In addition, the high clearness and easy-to-use navigation significantly reduce incorrect user input.

Industry 4.0

With the help of the SM IIoT Platform the CNC 93.00 can be extended by further communication interfaces. These include, for example, the widely used OPC UA as well as various API interfaces. This makes it easy to integrate the controller into industrial 4.0 concepts and to meet the extended requirements of drilling machines in a future-proof and convenient way.

Enrergy Efficieny and Performance

The modern and modular hardware architecture of CNC 93.00 allows extremly dynamic and precise machine drives with highest quality and little need for space. To reduce the required energy all servo drives and frequency converters are supplied via a DC bus of the central power supply. This minimizes costs and the required space.

CNC 93.00 – Fit for the Future

CNC 93.00 by the world market leader SIEB & MEYER in the field of CNCs for PCB routing machines is the perfect answer to all demands of high-precision, routing machines to be met by modern CNC controls.

SM IIoT Connect

![[Translate to Englisch:] CNC 95.00](/fileadmin/_processed_/2/f/csm_Produkt_Teaser-1000x1000_Plattform_64b019ae92.png)

In the CNC 95.00/CNC 93.00, the OPC UA interface is always available as a modern and flexible solution.

SM IIOT Connect clearly displays all important production parameters and also enables the CNC 95.00/CNC 93.00 to be automated via the standardised OPC UA interface. For example, part programmes can be loaded, CNC commands can be sent to the control or processing can be started or stopped.

Techncal Details CNC 93.00

Motion Controller MC93

• PU: Intel® Quad-Core™

• SDRAM: 4 GB DDR3

• Flash: 4 GB

• 2 x USB host

• 1 x COM interfaces

• Interface to PC: Ethernet

• 2 x digital bus via optical fiber connector (120 Mbit/s) to the drives MD95, FC95

• 1 x digital bus via optical fiber connector (12 Mbit/s) to the I/O system 84.06

• SD card (option)

• SSD hard disk (option)

Servo drive MD95 Nano with central voltage supply PS95

• Mains voltage 3 x 230 VAC to 250 VAC

• Rated current IN: 2 Arms to 32 Arms

• Peak current IS: 14 Arms to 57 Arms

• 1-axis, 2-axis, 4-axis and 6-axis design for rotary and linear AC motors

• Evaluation of incremental encoder, absolute encoder or linear measuring system TTL

• Digital bus via optical fiber cable (120 Mbit/s) for connection to MC93

Frequency converter FC95 with central voltage supply by PS95

Asynchronous spindles:

• Rated power: 6 kVA to 15 kVA

• Mains input voltage: 3 x 230/250 VAC, 50/60 Hz

• Rated current IN: 21 Arms to 35 Arms

• Peak current IS: 42 Arms to 71 Arms

• Output frequency f: 5,834 Hz

• Evaluation of speed sensors or operation without sensors

• Digital bus via optical fiber cable (120 Mbit/s) for connection to MC93

Decentral I/O-System 84.06

• DC supply: +24 V

• Inputs and outputs: 768

• Inputs: +24 V (active-high)

• Outputs: +24 V, 350 mA / short-circuit proof

• Data transmission via optical fiber cable (12 Mbit/s) / CRC monitored

• Serial interface for external PLC

• PD-Box with integrated interface for tool measurement and tool test

Comparison CNC 8x.00 - CNC 9x.00 by SIEB & MEYER -

Control Features

| CNC 8x.00 (Launched in 2005) | CNC 9x.00 (Launched in 2018) | Remark | |

|---|---|---|---|

| CPU processor | Coldfire MCF | Intel Atom | The choice of chips for the CNC 8x.00 is based on a 20-year-old architecture. Therefore, functionality of the CNC 8x.00 can only be retained and not adapted. The processor is not avaliable anymore on the market. SIEB & MEYER has a large stock, but this is ultimately limited. A certain amount of safety stock must be kept for service purposes. |

| Clock frequency | 220 MHz | 4x1.9 GHz | CNC 9x.00: excellent |

| Master storage | 16 MB RAM, 2 MB DPRAM | 4 GB DDR3 SDRAM, 4 GB eMMC FLASH | CNC 9x.00: excellent |

| Usability | Graphic program visualization. Intuitive and user-friendly human-machine interface, easy to operate and easy to learn. | Improved faster graphic program visualization. Intuitive and user-friendly human-machine interface, easy to operate and easy to learn. The simple customization of the interface according to process requirements can be realized by the OEM. | The operation mode and the use of command are completely consistent in both CNCs. The user interface of the CNC 9x.00 is more user-friendly. The simple customization for the end customer is particularly advantageous. |

| Compatibility and expandability | Master software planning and machine sequences. Non-standard modular upper programming limit. | Functional modularity via scripting. Support for technology upgrades in the future. | CNC 9x.00: excellent |

| Puzzle mode | Single-axis panels | Multi-axis panels | CNC 9x.00: excellent |

| Communication interface | Based on the SMDDE protocol (SIEB & MEYER own protocol) | SM IIoT Connect is included in the scope of delivery by default. OPC UA servers are available and support Industry 4.0 standards. | CNC 9x.00: excellent |

| Applicable scenarios | Traditional execution, small and middle serial production, stable environment | Production in large quantities, tailor-made for the modern factory | CNC 9x.00: excellent |

| Productivity | Standard 6 spindles and max. 6-axes IWS techniques | DWS 8/10/12 spindles, reserve for more axes | CNC 9x.00: excellent |

| Automization | Sequences, SMDDE | Fast process adaptaption by PEM scripts and standard OPC UA connection | CNC 9x.00: excellent |

| Quality assurance | Evaluating the logs retrospectively | Extensive logging through evaluation in real-time PDL data | CNC 9x.00: excellent |

| Data evaluation | Limited storage availability | Considerably more camera data and SLM surface memory possible | CNC 9x.00: excellent |

| Production Issues | Corrective drilling program, limited function | Easy process continuation of processes for the operator by the PIT function (production issue table) on the basis of permanent process data collection | CNC 9x.00: excellent |

| User interface funtions | Clear and fix user interface | The user interface can be adapted to the requirements of the customer | CNC 9x.00: excellent |

Applications

About SIEB & MEYER

SIEB & MEYER AG - Drive and control solutions of the latest generation

SIEB & MEYER was founded in 1962 and is a successful company in the field of industrial electronics. With around 260 employees worldwide today, we develop and manufacture control technology and drive electronics. Our core technologies include controllers for mechanical engineering and automation technology, servo amplifiers for a wide range of drives and frequency converters for high-speed motors and generators.

Contact

SIEB & MEYER AG

Auf dem Schmaarkamp 21

D-21339 Lüneburg

Phone: +49 4131 203 0

Fax: +49 4131-203 2000

You can find all sales contacts at: www.sieb-meyer.com/contact/sales

You can find all agencies and partners at: www.sieb-meyer.com/contact/offices-and-sales-partners