Highly Efficient Operation of High-speed Applications

Press releases

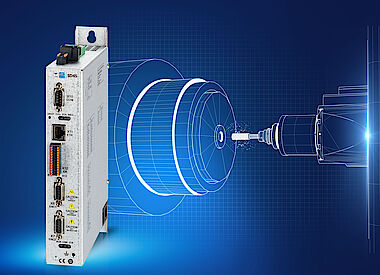

Drive controller SD4S by SIEB & MEYER

The drive controllers of the SD4S series by SIEB & MEYER are well-proven wherever highly efficient and loss-free operation of high-speed motors is required. SIEB & MEYER offers the SD4S series in a wide performance range, providing customers with a suitable solution for various application fields. At this year's SPS show in Nuremberg, SIEB & MEYER presents the complete product series with all performance classes up to 48 kW.

Thanks to its wide range of functions and performance classes, the SD4S is an all-rounder and offers a suitable solution for many different applications. The SD4S is available in three voltage classes, whereas the smallest device with 300 W @ 50 VAC features a small width of only 40 mm. Devices with an input voltage of 230 VAC reach output powers between 800 and 2400 W and three-phase devices with an input voltage of 400 VAC enable outputs of up to 48 kW.

Compared to the previous generation – the SD2S series – the construction volume of all product variants is reduced by up to 44 % while the output power remains the same. With its wide performance range, the highly efficient SD4S series meets the requirements of machine tools as well as those of dental milling machines or machines for superfinishing, for example in the watchmaking industry. Other application include wafer dicing machines in semiconductor manufacturing, turbo blowers and high-dynamic servo applications.

On the control side, the SD4S enables the operation of sensorless asynchronous, synchronous and IPM motors up to a rotating field frequency of 4,000 Hz (240,000 rpm), which is a unique feature in the market at present and allows customers to create new system designs. As the insulation strength in motors or spindles of smaller powers is often insufficient, the SD4S offers a galvanic isolation of the thermal contact.

A wide range of communication interfaces

All devices of the SD4S series are equipped with the safety function Safe Torque Off (STO). For the communication with the higher-ranking control the devices come with interfaces for CANopen and Modbus TCP. A multiprotocol real-time Ethernet interface optionally available for flexible communication between the higher-ranking control via EtherCAT (CoE), PROFINET IO or POWERLINK possible. The integrated real-time clock allows a precise analysis of errors as well as interactions with external events and processes.

Parameterization is carried out via a standard Ethernet interface, which replaces the USB interface that is prone to interference in industrial environments. The Windows software drivemaster4 serves as the central tool for parameterization, setup and simulations of the complete SD4x series. In addition to the drivemaster4 software, SIEB & MEYER offers customers the optionally available SpindleServiceTool (SST), a separate software especially for spindle manufacturers or repair shops to implement individual running-in sequences of spindles without external control.

In drivemaster4, SIEB & MEYER has further developed the tool "Motor Analyzer" already known from drivemaster2. The tool enables meaningful simulations of the entire drive controller operation. Users can simulate, view and output operating points, characteristic curves and output currents. The new FFT analysis of the simulated output current provides useful figures of the Total Harmonic Distortion (THD) of the motor current (THDi) and the motor voltage (THDu). This helps users to estimate the operating behavior and the motor heating more accurately.