SIEB & MEYER Relies on Switches at Pressure Foot for Depth Control

CNC NewsMachine manufacturers are facing new challenges due to increasing demands. PCB processing requires a precise and efficient surface detection in the field of depth control. For this purpose, SIEB & MEYER enhanced its range of measuring units for depth drilling/routing by the switch at pressure foot.

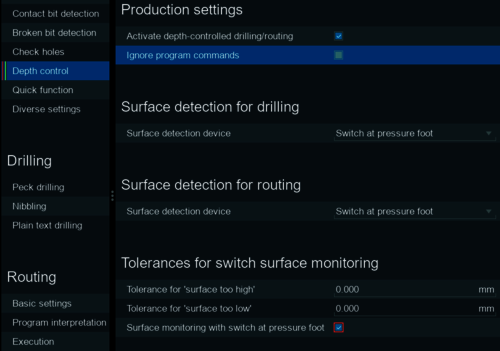

The hardware and software solution for the use of the switch at pressure foot for depth drilling/routing is provided by the SIEB & MEYER AG: The servo amplifier has been enhanced by a new input on the hardware side and new settings have been implemented in the Configurator on the software side, e.g. to enable monitoring of surface values.

The contact drilling module cannot be used for PCB processing with nonconductive board surfaces used for depth control. In this case, the switch at pressure foot is useful.

The switch at pressure foot delivers precise and repeatable measurement results. Compared to the measuring system at pressure foot, the switch at pressure foot is cost-efficient and easy to implement, e.g. when used in standard machines. The combination of a contact drilling module and a switch at pressure foot is an enhancement for high-end CNC machines, since it provides even better monitoring possibilities.

Thanks to enhancing the measuring units with the switch at pressure foot SIEB & MEYER provides another cost-effective, flexible and high-precision solution when it comes to surface detection for depth drilling/routing. Consequently, the increasing demands of the market regarding quality and process accuracy for PCB processing can be met in an economic and efficient way.